- Effective material traceability and quality assurance for the entire process of pipeline fabrication: from chemical analysis through to completed pipeline

- Track construction progress for any part of the pipeline, by length or volume, in either direction

- Shared project office and construction site progress visibility, for both onshore and offshore projects

- Fully scalable

Pipeline Construction

Improve every aspect of pipeline management

Material Traceability & Quality Assurance For The Entire Project Lifecycle

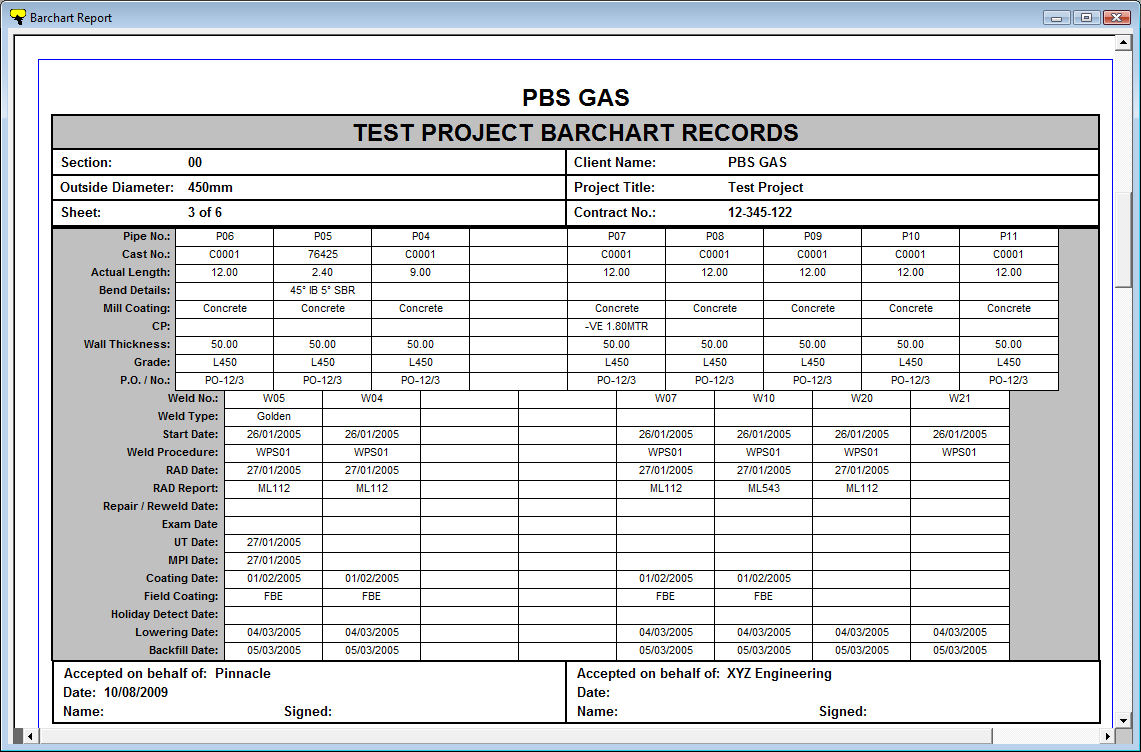

PipemaX provides effective material traceability and quality assurance for the entire process of pipeline fabrication from the chemical analysis of the casts of the steel through to the as-built and as-laid records of the completed pipeline.

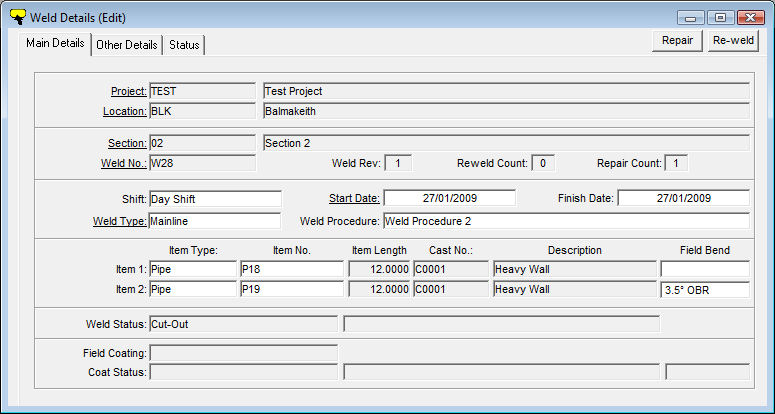

Quality assurance functions are an integral part of the system by recording all welds, repairs and re-weld details as well as visual, radiography, ultrasonic, magnetic particle and dye-penetrant examinations.

Full status information is maintained on material detailing the stages and its current location within the fabrication process. This also enables the system to record and display the pipeline length and volume at any given time also ensuring that a full material reconciliation can be performed as soon as the project is completed.

PipemaX offers users a real competitive advantage. Key features, such as, the comprehensive report, search and status functions, combine functionality and practicality to deliver improved pipeline management.

Improve efficiency & remove roadblocks

A Scalable System Designed For Large Projects

PipemaX is a fully scalable system, available as a stand-alone or multi-user server application.

It delivers all the benefits you would expect from an automated pipeline control and monitoring system - including reduced cost, improved efficiency and global availability of information.