Super User

System Integration

- A proven & structured approach to integrations

- Eliminate duplication & busywork

- Ensure that everyone has full visibility of mission critical data

Software Development

- World-class software development capabilities

- We build and iterate on our software according to customer feedback

- Bespoke software development facilities for large or complex projects

Production

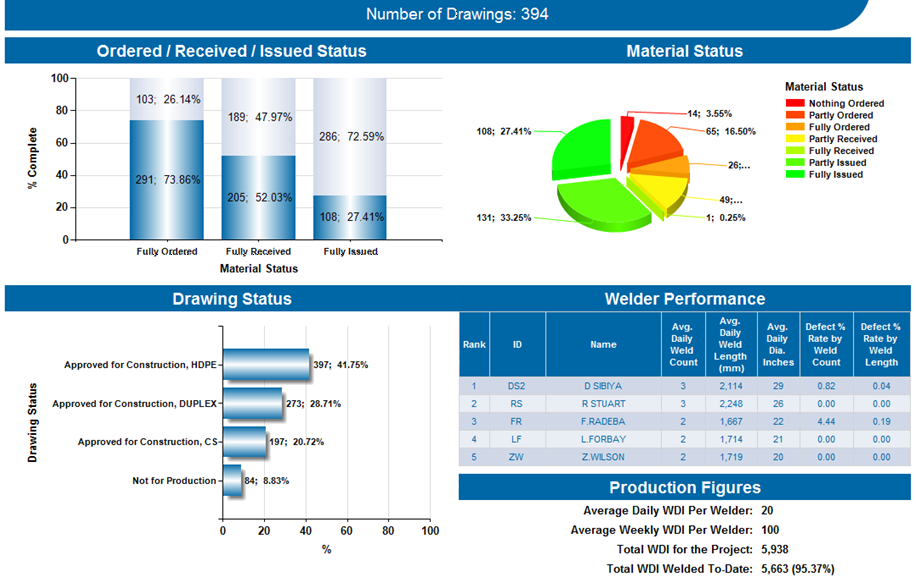

- Comprehensive information to help you successfully track and manage operations

- Access to multi-discipline information

- Tools for managing production and manufacturing personnel

- No more project delays

Support

- Hands-on support for large or complex projects

- A world-class helpdesk that's available around the clock

- Bespoke development and integrations available

Training & Advice

- Expedite operational growth with proven consultancy services

- Hands-on training & support that's tailored to your teams

- Get to grips with the full suite of MatriX technologies

MatriX System

What is MatriX?

MatriX provides complete control, visibility & traceability of all drawings, materials, construction and inspection activities

MatriX helps improve business efficiencies through enabling:- [list style="list-icons"] [li icon="icon-check-square-o"]Reduced cost and resources[/li] [li icon="icon-check-square-o"]Consistent accurate data entered one-time and shared by all project participants[/li] [li icon="icon-check-square-o"]Early identification of potential delays and problems[/li] [li icon="icon-check-square-o"]Instant visibility, and full history with audit trail [/li] [li icon="icon-check-square-o"]Knowledge and best practice that can be reinvested [/li] [/list]

MatriX Overview

MatriX Overview

MatriX supports all supply chain management, material traceability, quality control and progress monitoring processes including:-

[grid] [column size="1-3"]Materials Takeoff / BOM

Detailed and consolidated bills of materials for multi-disciplne projects of any size or complexity.

Supply Chain Management

Effective materials management and control across the complete supply chain and procurement cycle.

Inventory & Stock Control

Includes facilities for all materials, spare parts and consumables and ensures that material is always available to satisfy construction requirements.

Smart Material Allocation

Ensures continuity of fabrication by allocating material in project activity priority sequence and issuing to the project as soon as all activity requirements have been satisfied.

Fitup, Welding & NDT

Comprehensive facilities for the management and monitoring of all fitup, welding and NDT activities for major steel fabrication projects.

Inquiry & Reporting

Comprehensive Inquiry and Reporting facilities, all of which can be tailored and customised to meet individual client requirements.

MatriX allows all individuals and departments responsible for ensuring successful project execution to easily share critical information.

All MatriX software modules are functionally rich and include many user customisable features. They can be implemented as standard solutions that will provide immediate major project benefits. The modular nature of MatriX and the rapid application development software tools employed also means that custom solutions can be provided quickly and cost effectively. Integrated solutions are often provided that include interfaces with internal or external business applications such as CAD, planning, financial management or ERP systems.

Quality Control

- Monitor progress of all work and inspections

- Register all personnel and ensure their qualifications are valid

- Record all work, repairs and re-work

- Record all required inspections and results

- Comprehensive report package shows all inspection results

Material Scheduling

- Reconcile material availability with scheduled production requirements

- Match receipts and orders to suggest material optimum usage and highlight expediting requirements

- Continuously manage material allocations and fabrication schedules to optimise productivity

- Avoid production bottlenecks and delays

Inventory Management

- Comprehensive inventory management and stock control facilities for all materials, spare parts and consumables

- Automatic stock level management

- Automatic re-ordering

- Dynamic updates

- Multi-site operation